(Summary description)

(Summary description)

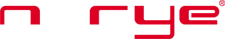

The 6S standardization management of the factory production site is an important task to improve basic management, the main starting point for improving safety management, and an inevitable requirement to promote standardized management. To this end, in order to further improve product quality and meet the diversified needs of customers, Norye will start the overall transformation of each factory workshop in the second half of 2021.

1. Improve the working environment and improve work efficiency.

Through the renovation of epoxy floor on the entire workshop floor and the division of relevant areas, a more comfortable working environment is created for employees and the cohesion of employees is improved.

(production workshop 6S management)

(Production workshop area management)

(Workshop staff work site)

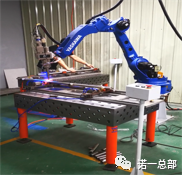

2. Update equipment, improve product quality.

Add new equipment, such as: automatic polishing machine, end automatic welding machine.

(automatic polishing machine)

(end automatic welding machine)

Create an independent R&D laboratory, invest R&D funds every year, continuously innovate products, and lead the industry with technology. Through quality standard testing and product ex-factory testing, we ensure that the quality of each ex-factory product is up to standard and relieve customers from worries. At the same time, we also participate in the standard formulation of third-party professional certification agencies such as TUV and SGS.

(a corner of the laboratory)

(a corner of the laboratory)

3. Increase publicity efforts to improve the quality awareness of all staff.

Through quality training and skill competition, we will further strengthen the education of quality and safety awareness of all employees, improve employee skills, and improve the overall quality of products.

(Quality Management Training)

In 2022, Norye will comprehensively transform and upgrade, standardize production site management, improve the quality of employees, ensure safe and civilized production, and achieve the goal of refined management. On June 25, Nuo paired the factory transformation promotion management team with the professional training of "6S Management in Production", and carefully sorted out the 6S transformation steps again, further unified and standardized the 6S lean management transformation standards, and continued to upgrade.

(production 6S management training)

In a word, Norye Factory will continue to improve the overall standardization management, which will definitely improve the quality and competitiveness of products, and create favorable conditions for better expansion of product market share. Norye will strive for "excellence and become a leader in the manufacturing industry of stainless steel bathroom products". Vision, take a solid step.

Scan the QR code to read on your phone